DIY Wood Pallet Shed: Build a Sturdy and Reliable Shed Today

Tired of overflowing garages and cluttered yards? Yearning for extra storage space without breaking the bank? Then building your own shed from reclaimed wood pallets might be the perfect project for you! This guide walks you through constructing a sturdy and reliable shed, utilizing inexpensive and readily available materials. Get ready to unleash your inner builder and transform your outdoor space.

Planning Your Pallet Shed Project

Before you dive into hammering and sawing, careful planning is crucial. Start by determining the size and location of your future shed. Consider the available space in your yard, local building codes, and the amount of storage you require. Sketch a basic design, noting the dimensions of your pallet-based walls, roof, and floor. This preliminary planning will prevent costly mistakes and ensure a smooth building process. You'll also need to source your pallets; inspect them carefully for rot, warping, and any protruding nails that might pose a safety hazard. Clean them thoroughly before starting construction.

Choosing the Right Pallets

Not all pallets are created equal. Look for heat-treated pallets, which are marked with the HT stamp. These are safer to use than chemically treated pallets (marked with MB). Avoid pallets showing significant signs of damage or infestation. Consider the size and condition of the pallets when planning your shed's dimensions. The stronger and straighter the pallets, the sturdier your shed will be.

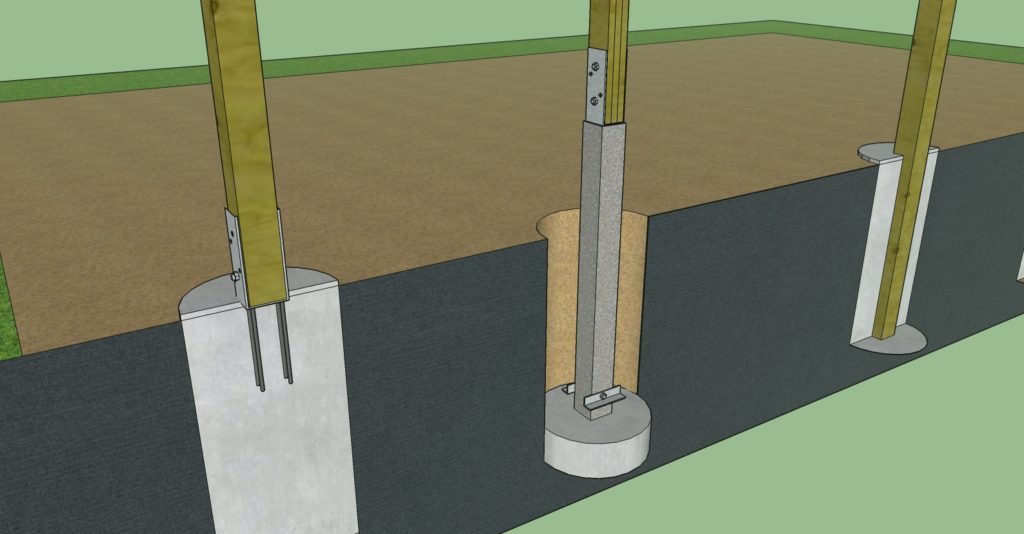

Building the Foundation and Frame

Constructing a solid foundation is essential for a stable shed. You can opt for a simple concrete slab, a gravel base, or even pressure-treated lumber for a raised foundation. Once your foundation is secure, you'll begin assembling the frame of your shed. Use sturdy 4x4 posts and 2x4 beams to create a robust framework that can withstand the weight of the pallets and the elements. Securely fasten all connections using appropriate screws and/or nails. Ensure the frame is perfectly square and level, as any imperfections will be amplified during the construction process.

Securing the Pallet Walls

Attach the pallets to the frame, ensuring a tight fit and utilizing sufficient fasteners. Consider staggering the pallets for added strength and a visually appealing look. For gaps between pallets, fill them with weather-resistant sealant or caulk to prevent drafts and moisture penetration. You may need to cut some pallets to fit perfectly and create a clean finish. Remember safety precautions and always wear appropriate protective gear.

Roofing and Finishing Touches

For your roof, you have several options: a simple gable roof, a shed roof, or even a flat roof (depending on local climate). Use appropriate roofing materials such as asphalt shingles, metal roofing, or even recycled materials, ensuring they're adequately waterproof. Remember to consider the weight of the roofing materials when planning your frame. Once the roof is complete, add a door and any necessary windows, ensuring they’re securely fixed to the frame. To protect your shed from the elements, consider applying a protective sealant or paint to both the exterior and interior. This will prolong the life of your structure and enhance its aesthetic appeal.

Adding the Finishing Touches

Personalize your shed! Add shelving, hooks, or other storage solutions to maximize its functionality. Consider adding a padlock to enhance security. A fresh coat of paint can significantly enhance the shed's appearance and help to protect it from the elements. Remember to clean up any debris from the construction process.

Safety First!

Throughout the entire project, prioritize safety. Wear safety glasses, work gloves, and sturdy footwear. Use caution when handling power tools, and always ensure proper ventilation when working with paints or sealants. Carefully inspect the pallets for nails and splinters before handling. If you're unsure about any aspect of the construction, seek assistance from a qualified builder.

Building a pallet shed is a rewarding experience. Enjoy the process, embrace your creativity, and revel in the satisfaction of creating something useful and unique from recycled materials. You’ll not only save money, but also contribute to sustainable living!